After printing phase, the transactions are carried out at post-printing divisions. Your order goes through the final phase at our divisions that are generally called “post-printing”.

It is possible to perform processes such as crushing-folding, thread sewn binding, American binding, spiraling, stacking, end-sheet tipping, book casing, local coating, cellophane, creasing line, perforation at our binding department. We can produce this and similar binding transactions serially and in a quality manner.

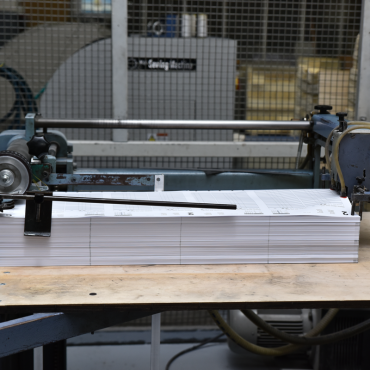

The works for which printing is completed at the offset department goes to crushing& folding band located at binding department. The sheets which are reduced to forms by crushing and folding are taken to stacking phase to produce the first samples of the inner blocks. If thread sewn binding is required, sewing is done by means of automatic and computerized machines followed by the end-sheet tipping process and delivered for edge, top and bottom trimming to the triple cutting knife, so that the preparation of the inner blocks of the work is completed.

The works that are to be printed on sheets are performed by paying attention to crushing places and crosses, while the processes are carried out in order. When the procedures of the works are completed, they are placed in different packings to prevent intermingling. Quality control is performed in each work flow of production.

Our casing division involves performance of processes such as solid board casing, cardboard cutting, emboss printing, foil-gilt printing, performance of some special cuts, sponge-lined cardboard, etc. Thanks to our fully automatic machine track, quality and fast production is ensured also at our casing division. Our expert and experienced staff may provide hard casing with any specifications desired.

After the printing processes are completed at our offset division, the coated papers for casing are cut into pieces by the cutting knife after cellophane is applied at the binding division and delivered to casing division.

At this division, the casing cardboards that are cut previously in the given dimensions and the coated papers for casing received from binding division are combined by the case-making machine. Then, the cases prepared by applying gilt or similar processes, if required, are delivered to binding division again.

As well as coated casings, casings made of artificial leather, coagulant and different materials may be produced by means of the same methods at the casing department It is also possible to apply gilts and embosses on the casings. Besides, the same procedures may be done on leather materials.

When the production procedures of the book cases are completed, they are placed on different pallets to prevent intermingling. Necessary controls are undertaken in order to ensure that the processes are carried out properly during the production. Thanks to our target oriented working discipline, we have become a pioneer, lodestar in the printing sector.